EZBasket™

Green and Sustainable Concrete Slab Load Transfer.

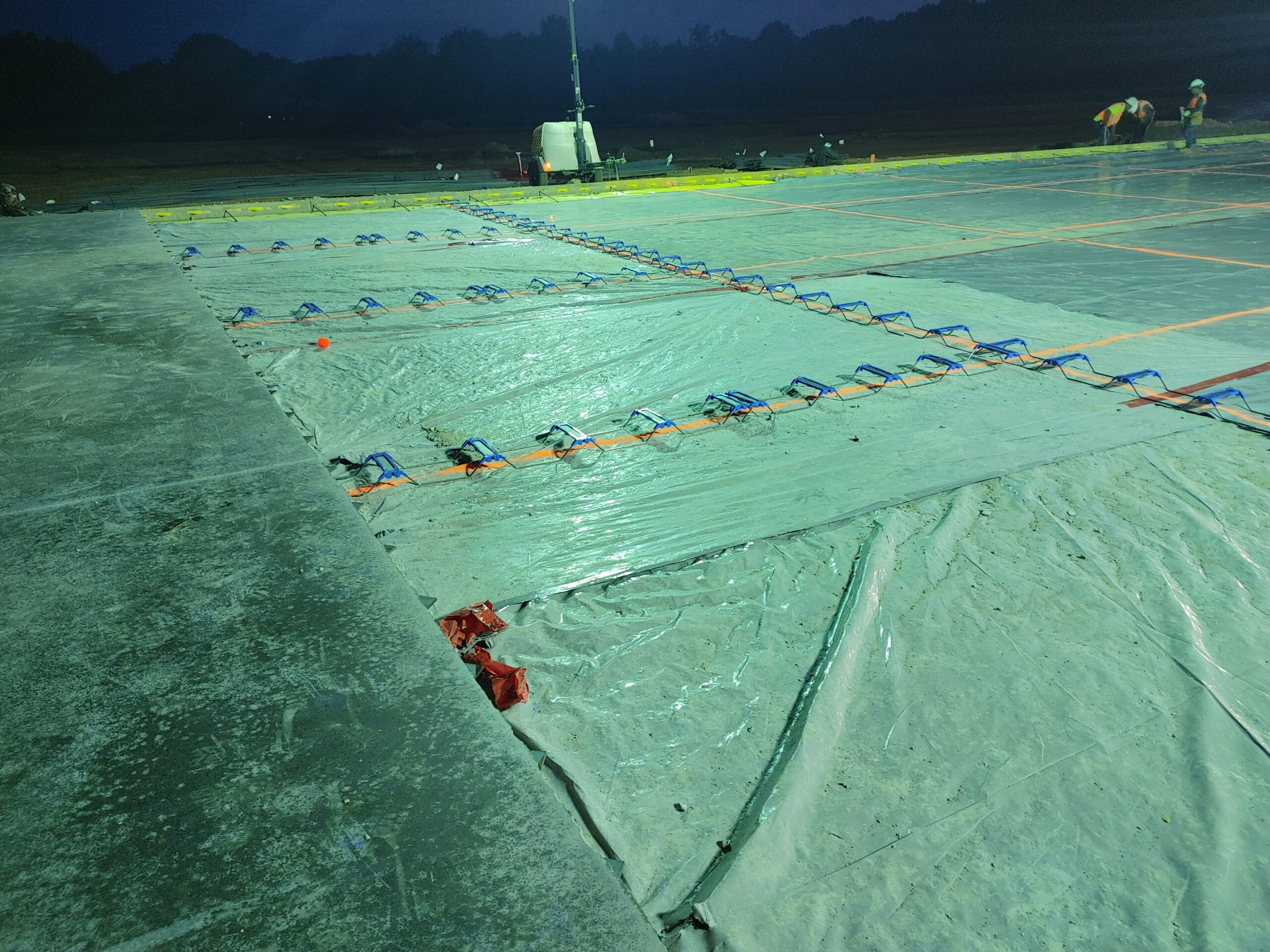

Concrete flooring and paving must have the ability to withstand the rigors of service such as the abrasive and concentrated loads of wheeled traffic across the joints.

EZBasket™ (the Basket assembly) is designed to help you reliably deliver a serviceable slab in a highly competitive environment. Designers will recognize the benefit of EZBasket™ in any joint reinforcement planning.

EZBasket™

Designers will recognize the benefit of the EZbasket™ in any joint reinforcement planning.

Utilizing McTech unique product of wire, plate and compressible center geometry and a factory applied debonding agent, the EZbasket™ assembly helps you:

- Save labor

- Provide a more efficient use of steel when compared to continuous mats

- Minimize your liability in warranty and retained earnings

- Limit your liability

- Deliver a greener and more sustainable slab-on-ground

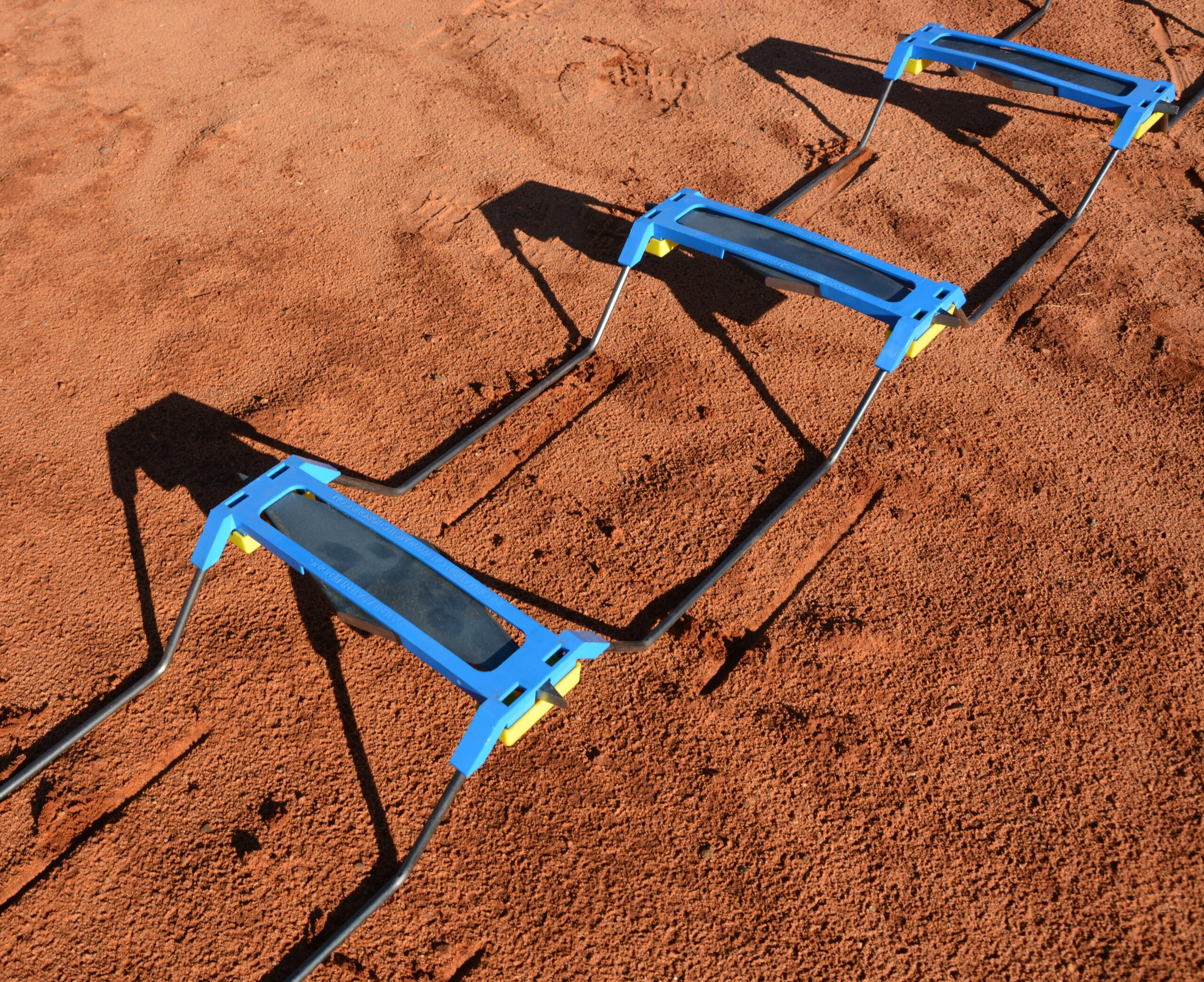

EZbasket™ Fast, Simple Assembly

- With the use of the EZbasket™ jig assembly is just a quick snap of the side frame into the specially designed plastic sleeve, snap in the dowel sleeve clips and the assembly is complete.

- Easy to handle, can be carried and installed by one person during concrete placement.

- EZbasket™ components are crated /boxed /palletized as required for easy handling and reduced freight costs.

- EZbasket™ are available through our national distribution network.

US PATENT NO. 11,149,385

- All EZbasket™ products are manufactured by McTech Group, Inc.

- Tapered plate dowels are cut from hot roll ASTM A36 bar within a 0.010 tolerance.

- Round dowels will be cut from material meeting the requirements of AASHTO. M255M/M255, AASHTO M334, ASTM A276, ASTM A312 or ASTM A1035(CS, CM and CL) The grade shall be specified by the purchasing agency.

- Dowel sleeves, both tapered and round, are molded from polypropylene –no break Side frame supports are fabricated from 0.283 to 0.375 diameter cold drawn wire per ASTM 510/A510.

- The finished field assembled EZbasket™ will position the dowels, tapered or round within +/-0.015 “of the required slab placement depth.

- EZbasket™ is stackable after assembly for transportation to the jobsite and will remain stable under concrete placement.

EZBasket™

Specifications and Configurations:

- All EZbasket™ products are manufactured by McTech Group, Inc.

- Tapered plate dowels will be cut from hot roll ASTM A36 bar within a 0.010 tolerance.

- Round dowels will be cut from material meeting the requirements of AASHTO. M255M/M255, AASHTO M334, ASTM A276, ASTM A312 or ASTM A1035(CS, CM and CL) The grade shall be specified by the purchasing agency.

- Dowel sleeves, both tapered and round, shall be molded from polypropylene –no break Side frame supports will be fabricated from 0.283 to 0.375 diameter cold drawn wire per ASTM 510/A510.

- The finished field assembled EZbasket™ will position the dowels, tapered or round within +/-0.015 “of the required slab placement depth.

- EZbasket™ is stackable after assembly for transportation to the jobsite and will remain stable under concrete placement.

Configurations:

Plate Dowel Baskets

.375” x 18” O/C

.375” x 24” O/C

.500” x 12” O/C

.500” x 18” O/C

.500” x 24” O/C

Round Dowel Baskets

0.750 – 1.00” x 12” O/C

1.250-1.500” x 12” O/C

0.750 –1.00” x 18” O/C

1.250-1.500” x 18” O/C

0.750 -1.500” x 24” O/C

EZbasket™ Fast, Simple Assembly